|

|

#151

|

||||

|

||||

|

Only Lambda Project would know if the input is ok to handle this on the ECU.

Do you have to rescale the input in the ECU software. If not I guess the scaling is the same so the voltages will be similar. The lambda probe generates its voltage via a chemical reaction a bit like a battery. When the gases flow over it the oxygen in the gas causes a chemical reaction in the sensor and it generates a small voltage. At idle or cruise the ideal mixture is 14.7:1 AFR which causes the lambda to generate 1.0V lambda. As you drive harder the car richen up and the voltage decreases due to less oxygen content. So in theory if both lambda probes wideband and narrow band generate 1V at 14.7 then both will reduce in voltage, so not a problem. However after a quick Google i expect the wideband may produce 2.5v at 14.7, which may not be a problem for the ECU but the Software will need rescaling. Maybe it provides a narrowband/wideband soft switch |

|

#152

|

||||

|

||||

|

After making the connection, it is indeed necessary to calibrate or rather make a table of values in Volts / AFR / Lambda to interpret the values it returns in 0-5 Volt. There were no problems, everything worked correctly. The goal is to perform Datalog then reverse the normal 0-1v connection. I made the connection using a 3-point inverter key, so that going from 0-1v or 0-5v is in just a moment. Intercepting PIN 21 of connector B136 of my ECU.

The table that the wideband brought me helped. but he still needed a parameter data collection to have the initial calibration. observing the read AFR and at the same time taking note of the value of Voltage that the datalog throws. At the same time, varying the fuel load compensation allows a specific rpm range to be varied in real time at an AFR / lambda range in order to take the necessary readings. Last edited by viper1982; 07-06-2020 at 06:15 PM. |

|

#153

|

||||

|

||||

|

Personally I'd just run the wideband with it's own software in a separate window.

Just log the richen up with a 3rd gear pull from 2500rpm to 7000rpm to make sure your happy i.e 14.7AFR - 11.2AFR. It doesn't really need the precise cell by cell logging and tuning that the Ignition timing needs. Just by looking at the fuel map you can set it to what you want to achieve. If it doesn't achieve what it's calibrated/mapped too, then that's probably down to very bad timing setup, MAF calibration or Injector calibration. But on a fairly standard car with OEM injectors, MAF etc... it should be pretty close. Also remember to free air calibrate your lambda probe to make sure it's reading accurately |

|

#154

|

||||

|

||||

|

For a good free air calibration would it be necessary to remove it if or if the downpipe or is it enough that the vehicle is not running at least from one day to the next so that there are no gases inside that alter the calibration? what do you recommend?

|

|

#155

|

||||

|

||||

|

For the wideband it's always best to calibrate it removed. Because gases and oxygen content at the down pipe will not be representative of clean air,.

|

|

#156

|

||||

|

||||

|

I am considering changing the Wideband instrument that I have been using, I am not convinced by the result to do datalogs. In the Rich & ideal regime, the voltage sampling in the datalog is good, but in the most important range close to the 10/11 AFR values, the output is very fluctuating.

I was looking at two models to see if you have experience with one. The Innovate MTX 3918 Plus & AEM X series 30-0300.- Both instruments equip the same Bosch LSU 4.9 sensor My current Wideband Prosport equips that too, but the truth is that I am not convinced by the quality of measurement to look for something fine. In WOT condition according to my prosport all the "rich" 10: 1 always. And I have the original tune it is impossible that it is always 10: 1. (I have already done free air calibration) I also bought a new Bosch LSU 4.9 sensor to rule out any problems, but I am almost certain that the problem is the instrument is simply not good. Do you have a reference regarding these two brands and models? Any recommendation? |

|

#157

|

||||

|

||||

|

I use an innovate for live tuning in an exhaust tailpipe clamp.

I also have the same model innovate hard wired into my down pipe, with an innovate gauge in an A pillar pod. |

|

#158

|

||||

|

||||

|

Good to know that the Innovate brand has worked well for you then. Finally I acquired the Innovate MTX L Plus which I found useful that in addition to the analog output of 0-5v it has the option of connection via serial port. Also modification of some parameters by this last method. I will wait for the install to arrive and continue with what I was about to start doing. The results of readings with the prosport leave much to be desired.

|

|

#159

|

||||

|

||||

|

Prosport are budget gauges.

Not as good as the original Defi |

|

#160

|

||||

|

||||

|

As you say, even so, I cannot complain about the Prosport brand in the following instruments that I have have given me excellent results:

* oil pressure (electrical) * water temperature (electrical) In these two instruments of the prosport series EVO digital line I cannot say anything wrong, on the contrary. The water temperature coincides with the ECU reading at a difference of 1 ° Celsius. Tested with a thermographic FLIR camera as well. Then I compared the oil pressure with the reading of a mechanical workshop instrument that I use to work and it is exact. Only on the Wideband instrument did I find that it is not very accurate. That if the reading frequency is very good, the response is fast. Use the BOSCH LSU 4.9 Sensor. The initial heating resistance of the instrument is also relatively fast in about 15/20 seconds it is ready to work. What fails is in the reading of ranges below AFR 12/13 ... there the precision is relative. And it is not to be trusted. I comment this to avoid perhaps that someone else happens and save money, and directly go to a brand of this type of more reliable instruments such as innovate or AEM. There are others like Autometer but the truth is that reading and winding features are expensive and do not have many features than others. In fact, as far as I could see, the highest reading range is owned by Innovate, which ranges from 7.25 / 7.50 to 22 AFR. Aem goes from 8 to 20. The others only go from 10 to 20. |

|

#161

|

||||

|

||||

|

Scott, is the "MAF scaling" procedure very complicated to do the procedure in order to see if the value it brings is correct without having altered the diameter or anything of the intake system? I want to try doing it just out of curiosity and the intention to learn.

|

|

#162

|

||||

|

||||

|

Quote:

If you can switch closed loop lambda fuelling off you could adjust the MAF scale at idle and see an immediate effect. It can be used to cheat the fuelling. Instead of adjusting fuelling cell by cell at the top end, if you want to adjust everything by say 0.5AFR across the board you can shift it all by adjusting the MAF at the voltages that are being hit. But your AFR values loaded in the fuel map wont then equal what you actually read on the Lambda because its being offset by the adjusted MAF. This doesn't matter for the car but for me I like the AFR tables to be close to actual AFR readings. |

|

#163

|

|||

|

|||

|

Hello. Subaru impreza GT my 99 ecu 1644500505

I have had a subaru my99 for several years. I have a modded file. I installed a large intercooler. Now I do not want to rush from below. Can anyone help? Maybe you can do pops & bang or some help with locating the map. I add intercooler big Thank you in advance for your help. I read/write pcm flash. edit winols Thx |

|

#164

|

||||

|

||||

|

Hello, I understand that you do not need any reprogramming with the installation of a larger intercooler, to make pops & bangs the only thing you have to do is delay the ignition map in ranges that do not affect the operation of the vehicle, that is, in the low areas. negative values are commonly used. and the range of RPM that you choose, for the vehicle to function it must be in change and in deceleration it does not operate in neutral.

If you have a catalyst I do not recommend that you do the pop & bang. |

|

#165

|

|||

|

|||

|

Quote:

I don't have a catalyst |

|

#166

|

||||

|

||||

|

Quote:

What are you using to log and flash images back ? |

|

#167

|

|||

|

|||

|

Quote:

https://ecutools.eu/chip-tuning/pcmflash/module-16/ Found ignition maps in winols. I don't have an address here because I have another laptop in the garage on another laptop. What map should be changed after changing the intercooler? Large in the bumper so that it does not choke when changing gear. |

|

#168

|

||||

|

||||

|

Quote:

Sounds like you may have other issues if its bogging down so severely. |

|

#169

|

||||

|

||||

|

Quote:

|

|

#170

|

|||

|

|||

|

Quote:

Hello. Can someone see pops bang in this file? ALS, LC Is it possible? On what maps. You will help, I will test. thx http://www.southeastscoobies.co.uk/v...9&d=1586359039 |

|

#171

|

||||

|

||||

|

Scott, I'm making the Target Boost board to start playing a bit and playing the tune. I am based on the AE802 Revision which is the most modern and has progressive WGDT tables as well as Boost. But I want to push the TD04L to its limits. As I saw that you commented that the "ECUTEK TEK2: 15.96psi, falling to 11.47psi on the red line" I wanted to know if you have the impulse map of it to copy it?

If you had the WGDT table it would also be ideal, but I must compensate it anyway since I change the 3 Port Solenoid system so everything I am testing I must lower the WGDT by 25 to 30% to avoid Overboost. |

|

#172

|

||||

|

||||

|

I've been following this since the start ,very interesting and would like to get involved, but unfortunately no idea what you are talking about.

|

|

#173

|

||||

|

||||

|

No problem Frenchie. All this thread can be very useful if one day you join the world of modifying your vehicle through ECU Reflash. At least as a starting point or orientation. I am already doing it but many doubts arise along the way.

|

|

#174

|

||||

|

||||

|

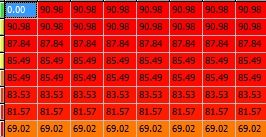

Hi Viper,

TEK 2 isn't a great deal different to Prodrive with only about a 0.5 psi difference across the board. So I pulled the TEK2P5 Data into the Target Boost and Wastegate Tables for you to view below. This is just extracted from a spreadsheet record I had and pulled into ECUEdit : Max Wastegate Duty  Target Boost  I'm not sure how good they are as I have not run them. Make sure your fuel and ignition tables are adjusted to cater for the extra boost and that you don't run off the top of the load scale. |

|

#175

|

||||

|

||||

|

Go on Terry you know you want to learn a new skill and have a play with the STI really. ECULabs runs a car just like yours so they will have just the tools for you.

|

|

#176

|

||||

|

||||

|

What interesting information, that TEK2P5 ECU in which GC8 model was it implemented you know? Do you know if the TD04 is capable of handling that?

|

|

#177

|

||||

|

||||

|

Quote:

I had a TEK3 with a VF28 before I switched to Apexi. I do have the calibration tables though, but not confident I have the complete ROM image. At the low end of the rpm range the TD04 probably physically can't achieve the target boost but if you don't ask you don't get.(sorry that may be a bit of an English saying). With all my tunes I tend to put unrealistic low rpm high target and high wastegate duty to try and make it as responsive as possible when at 50% throttle. This works very well on the DBW cars where you can target 80% boost at 50% throttle making for a very responsive car that is quite relaxing to drive briskly. Setting it to 80% ensures when you do want to drive more spirited and WOT the car still has 20% more boost to give. The Prodrive calibration for the DBW STi was a very linear boost curve. With boost gradually increasing with rpm and theottle %. Max boost was very high up the rpm range. I assume trying to emulate a normally aspirated car. I hated it on my 2007 STi PPP because you had to drive it full throttle and high rpm to get it to boost. It also had a hesitation/surge at 2100rpm when crawling in traffic which I could feel and see in the tables, so I sorted that out too. I'll try and put up a calibration table for the DBW later |

|

#178

|

||||

|

||||

|

Very interesting information, any other information you can attach to the TEk3 will be welcome for guidance, be it a fuel or spark map.

I have the doubt based on what you just mentioned, I have seen that there are two ways to map the WGDT, aggressive and linear (such as the TEK3 that you share and Prodrive) and on the other hand I see that many original STI ECUs come with very progressive Boost and WGDT curves. (Like the AE802, the newest revision of the series) From what I read I understand that your bets on the linear and abrupt in the whole range to obtain a more jealous and responsive vehicle, right? Are there any pros and cons of using these more violent wgtd curves? Another thing, the WOT tests are correct doing them in 3rd from 2k to 6.4k? * At the moment the tests that I have done with the slightly modified prodrive map I have had tests at WOT from 2k to 6.5K of AFR 11.1 /11.2 Dropping to 10.6 from 6,000 RPM and beyond. reading with Innovate wideband with immediate oxygen sensor in the Turbo outlet. which I think is adequate. I still do not understand very well the fuel table that lambda uses since it is a relationship between several things, it is not a fuel table only. but since at the moment I have not had to alter it I have not worried. Last edited by viper1982; 11-09-2020 at 05:32 PM. |

|

#179

|

||||

|

||||

|

Based on what you shared Scott I made a somewhat more conservative custom to boot and test. I share in the image, the WGDT cycles are so low since a few days ago I changed the OEM system of my vehicle which was 2-port solenoid, for a Pierburg 3-port. Increase the entire prodrive table by 10%, and increase the entire wgdt range by 10% to compensate for the extra boost and be able to carry it out.

In addition to that table, he had already removed 28% of the total for the change from 2 port to 3 port. Consider not altering the first row to force things to boost as soon as possible. (I don't know if it's correct) I am obviously open to any suggestions. I already uploaded it to the ECU but I did not manage to go out to test today, tomorrow if I can comment on the result. Last edited by viper1982; 11-09-2020 at 11:47 PM. |

|

#180

|

||||

|

||||

|

I have a question, in the case that I set a ridiculously high waste gate duty cycle value, but at the same time, I do not modify the corresponding table of boost target. What's going on? How does the ecu handle this situation?

I know that if a very low wgdt value is placed, only the desired momentum is not reached, but in the reverse situation? |

|

#181

|

||||

|

||||

|

Quote:

This is quite common for a dyno tuned car using 3rd gear only. On the drive home the owner gives it 3/4 throttle on the motorway in 5th at 3500rpm. The turbo over achieves and oscillates or in some cases hits the fuel cut limit. When road tuning, use 3rd for the bulk of it but then try a 4th or 5th from 2500rpm to about 4500rpm to check for overshoot. |

|

#182

|

||||

|

||||

|

Very well, I'll keep it in mind. Thanks Scott.

At the moment I have only managed to compensate well for the boost curve, completely eliminate the maximum peak, (flatten the curve) and the acceleration is very constant and even. I had to reduce the WGDT more (41%) over the original value of my prodrive table. Since I did a measurement and the Wastegate of the kinugawa I use has 11.60 PSI opening spring. (Test pressure by applying a 0% offset to the entire table over the entire Load vs RPM range.) I base my initial calculations of compensations having a wastegate of 7 PSI (the original) that error led me to waste a lot of time compensating the tables and generating small pressure peaks at WOT in 3rd from 2,000 RPM to 6,400 RPM, at the maximum point boost that I achieve in a range of 3,200 RPM exerted a peak of ≈18 PSI and then fell to the ≈15.60 psi of table. Something unnecessary and inefficient I think. I share the datalog through megalogviewer of how the original curve with 2-port solenoid was and superimposed the 3-port solenoid curve with various offsets already applied. (Don't alter the target boost) yet ... |

|

#183

|

||||

|

||||

|

Quote:

After testing the limits with the 2-port system, I made the change to 3-port and with this it was the same at very high speed the td04 does not provide more than 12 PSI at 7,000 RPM. Last edited by viper1982; 06-11-2020 at 02:16 PM. |

|

#184

|

|||

|

|||

|

Hello Scott, viper.

Scott, Viper and others. I did something in the maps similar to ecutek and the car drives well. Generally only deals with diesel in winols. More amateurish. Subaru my99 / 00 gt. Only a problem up to 2500 rpm. Maybe you have any maps for this ecu, tek1, tek2, prodrive? I have to compare and see what is modified. Please contact us or send an email to manager.sakowski@gmail.com Of course he will send his? |

|

#185

|

||||

|

||||

|

Quote:

Many of the MY99 maps are discussed in this thread. Some threads have links to definition files that you can use to decode the information. All comparisons have been previously covered if you care to read through and know how to use the information provided. |

|

#186

|

|||

|

|||

|

Quote:

Do you have an ignition map from tek2? I'm okay with the ignition to pops bang? Ist good? Only zeros are marked on the map. Last edited by teedy6; 14-12-2020 at 12:48 PM. |

|

#187

|

|||

|

|||

|

Quote:

What do you think about it? |

|

#188

|

||||

|

||||

|

With reference to your private message request to email you TEK images. I do not have the full bin/hex file only details of the various performance tables/maps that I either obtained through research or read directly from ECU address locations, whilst attached to my car. Most of the info obtained is discussed above.

The only complete bin/hex that i have are those that are already available online of standard tunes. |

|

#189

|

||||

|

||||

|

You must be much more detailed about the modifications and improvements that your MY99 & 00 ej205 engine has. From what little I could see in my opinion you are generating too much Boost at high speed (If you have the OEM td04l) Then the ignition advance is very high, I think you must have Detonation.

|

|

| Currently Active Users Viewing This Thread: 4 (0 members and 4 guests) | |

|

|